Steve MacDow

Member

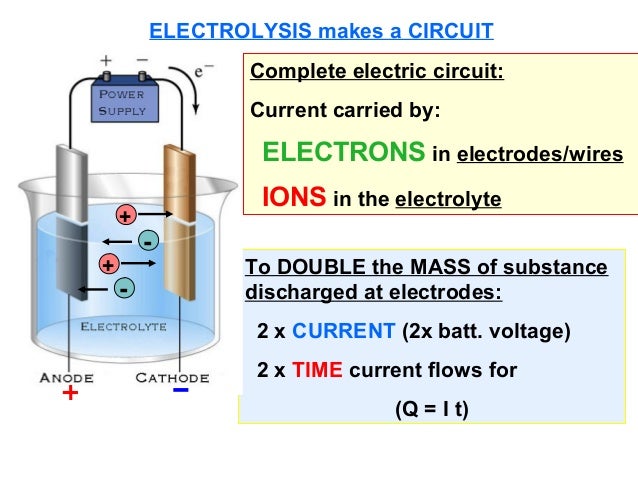

I manage a restaurant, and I have a couple pieces of old stainless equipment sitting out back. I thought I would scavenge a sheet or two off of them to set up an e-tank. I was looking at an old stainless steel deep bar sink that's missing a couple legs, and I thought I could cut a couple panels off that and then...duh...I realized the sink itself is a perfect tank. I can put it on a wooden frame, fill it with water, and the sink itself becomes the anode. Perfect.

Now the questions....

First, just how much hydrogen is produced?

The best spot I have for it logistically is in my basement. However, I don't have good ventilation down there, and I have a pilot light on a gas water heater as well as a gas furnace. Last thing I need to do is blow up my house trying to restore a $6 rusty pan.

My only indoor option is in an unheated mud room. Two exterior doors and two windows, so I can get plenty of cross ventilation. However, I live in New Hampshire, so in a couple month it will drop below freezing and stay there for a couple months. Pretty hard to use an e-tank that is frozen solid.

How does water temperature affect the electrolysis process?

An advantage of my sink setup is that I can hook a hose up to the drain and start with warm water each time I want to use it. Unless I find a mother lode of old iron somewhere, I don't see myself needing to run it all that often. Will it work to start with warm water even if the ambient temp is well below freezing?

Of course for now I can set it up outside. I'm just trying to think about what to do when cold weather sets in.

Thanks in advance for any advice!

Now the questions....

First, just how much hydrogen is produced?

The best spot I have for it logistically is in my basement. However, I don't have good ventilation down there, and I have a pilot light on a gas water heater as well as a gas furnace. Last thing I need to do is blow up my house trying to restore a $6 rusty pan.

My only indoor option is in an unheated mud room. Two exterior doors and two windows, so I can get plenty of cross ventilation. However, I live in New Hampshire, so in a couple month it will drop below freezing and stay there for a couple months. Pretty hard to use an e-tank that is frozen solid.

How does water temperature affect the electrolysis process?

An advantage of my sink setup is that I can hook a hose up to the drain and start with warm water each time I want to use it. Unless I find a mother lode of old iron somewhere, I don't see myself needing to run it all that often. Will it work to start with warm water even if the ambient temp is well below freezing?

Of course for now I can set it up outside. I'm just trying to think about what to do when cold weather sets in.

Thanks in advance for any advice!